POLYURETHANE FOAM

POLYURETHANE FOAM

RAKU-PUR RAKU-PUR 32-3250-8

SOFT INTEGRAL FOAM, THIXOTROPIC

RAKU-PUR RAKU-PUR 32-3250-8

SOFT INTEGRAL FOAM, THIXOTROPIC

Description

RAKU-PUR® 32-3250-8 is a thixotropic, two-component polyurethane system. It consists of a filled resin component A and a hardener component B (MDI). The system contains no solvents, plasticizers or halogenated hydrocarbons. It is characterized by:

- High sealing performance

- Very low foam density

- Very low water absorption

- Compact, hydrophobic integral skin

- High mechanical strength/tear resistance

- High tensile strength

- Very short cure and assembly time

- Good value/performance

- Good mounting adhesion to metal surfaces

- Listed UL 50

Description

RAKU-PUR® 32-3250-8 is a thixotropic, two-component polyurethane system. It consists of a filled resin component A and a hardener component B (MDI). The system contains no solvents, plasticizers or halogenated hydrocarbons. It is characterized by:

- High sealing performance

- Very low foam density

- Very low water absorption

- Compact, hydrophobic integral skin

- High mechanical strength/tear resistance

- High tensile strength

- Very short cure and assembly time

- Good value/performance

- Good mounting adhesion to metal surfaces

- Listed UL 50

Temperature resistance

Long-term -40°C to + 100°C

Short exposure up to + 160°C

Temperature resistance

Long-term -40°C to + 100°C

Short exposure up to + 160°C

Application

The product is used for the production of formed-in-place foam gaskets (FIPFG) and of moulded foams. The hardness of the material can be adjusted to the specific application by changing the mixing ration.

Application

The product is used for the production of formed-in-place foam gaskets (FIPFG) and of moulded foams. The hardness of the material can be adjusted to the specific application by changing the mixing ration.

Processing

Before use, the component A must be homogenized, as additives tend to cause phase separation. The density of the material can be adjusted to the processing specification of 0.80 – 0.90 g/ml by adding dispersed air through stirring. The air helps to ensure an uniform foam structure. The component B is very sensitive to moisture and must not be stirred. Due to its high reaction rate, the system is usually processed by two- component mixing and dispensing machines.

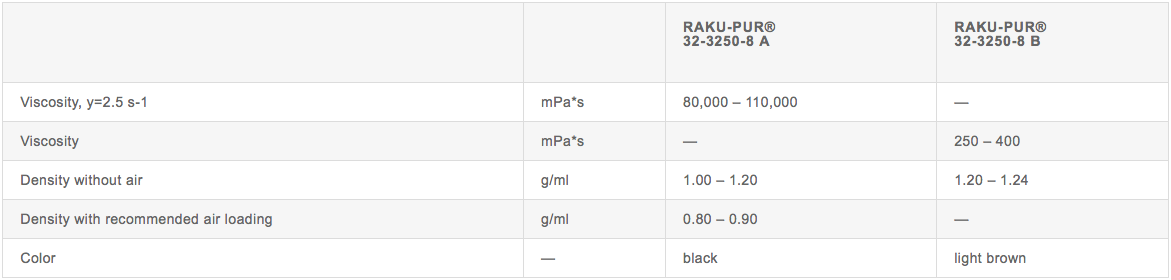

Raw components data

Processing data

Processing

Before use, the component A must be homogenized, as additives tend to cause phase separation. The density of the material can be adjusted to the processing specification of 0.80 – 0.90 g/ml by adding dispersed air through stirring. The air helps to ensure an uniform foam structure. The component B is very sensitive to moisture and must not be stirred. Due to its high reaction rate, the system is usually processed by two- component mixing and dispensing machines.

Raw components data

|

RAKU-PUR® |

RAKU-PUR® |

||

|---|---|---|---|

| Viscosity, y=2.5 s-1 | mPa*s | 80,000 – 110,000 | — |

| Viscosity | mPa*s | — | 250 – 400 |

| Density without air | g/ml | 1.00 – 1.20 | 1.20 – 1.24 |

| Density with recommended air loading | g/ml | 0.80 – 0.90 | — |

| Color | — | black | light brown |

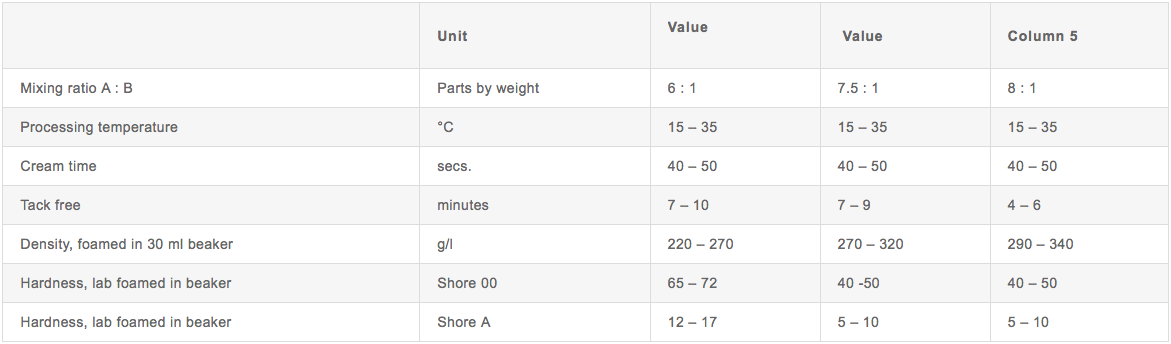

Processing data

| Unit |

Value |

Value | Column 5 | |

|---|---|---|---|---|

| Mixing ratio A : B | Parts by weight | 6 : 1 | 7.5 : 1 | 8 : 1 |

| Processing temperature | °C | 15 – 35 | 15 – 35 | 15 – 35 |

| Cream time | secs. | 40 – 50 | 40 – 50 | 40 – 50 |

| Tack free | minutes | 7 – 10 | 7 – 9 | 4 – 6 |

| Density, foamed in 30 ml beaker | g/l | 220 – 270 | 270 – 320 | 290 – 340 |

| Hardness, lab foamed in beaker | Shore 00 | 65 – 72 | 40 -50 | 40 – 50 |

| Hardness, lab foamed in beaker | Shore A | 12 – 17 | 5 – 10 | 5 – 10 |

measured at 20 °C, 30 ml formulation, laboratory stirrer 1800 rpm.

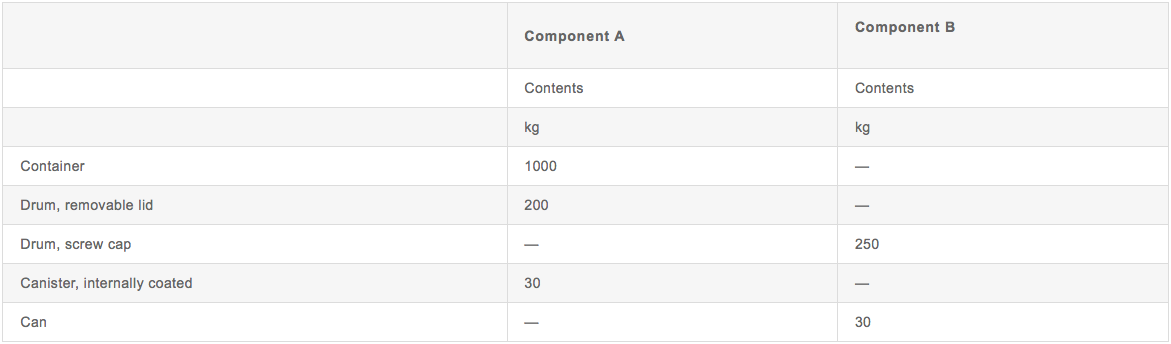

Standard shipping containers

| Component A |

Component B |

|

|---|---|---|

| Contents | Contents | |

| kg | kg | |

| Container | 1000 | — |

| Drum, removable lid | 200 | — |

| Drum, screw cap | — | 250 |

| Canister, internally coated | 30 | — |

| Can | — | 30 |

Storage

Original containers may be stored at ambient temperature (10 °C – 35 °C) for 9 months. At temperatures below + 5 °C the hardener component B may crystallize. Since both components are affected by air moisture, containers should be kept tightly sealed.

Health and safety at work

The workplace in which the material is being used must be well ventilated. All applicable health and safety regulations governing the use of reactive resins and their hardeners must be observed. Please also observe the respective safety data sheets.

Standard shipping containers

Storage

Original containers may be stored at ambient temperature (10 °C – 35 °C) for 9 months. At temperatures below + 5 °C the hardener component B may crystallize. Since both components are affected by air moisture, containers should be kept tightly sealed.

Health and safety at work

The workplace in which the material is being used must be well ventilated. All applicable health and safety regulations governing the use of reactive resins and their hardeners must be observed. Please also observe the respective safety data sheets.